What could happen if a business does not have proper inventory management?

Think about it—empty shelves, delayed orders, wasted stock, and frustrated customers. Sounds like a nightmare, right? It’s a scenario many businesses face when inventory slips through the cracks.

You might not notice it right away, but over time, those little issues stack up into big problems. Revenue drops, customers leave, and suddenly, you’re scrambling to fix a mess that could’ve been avoided.

So, how do smart businesses keep winning in 2025? What systems, strategies, and tech are they using to stay lean, fast, and profitable? That’s what this guide is all about.

What Is Inventory Management?

Inventory management is how a business tracks its products—from ordering and receiving them to storing, tracking, and managing the costs of everything it sells.

Managing your inventory well is very important if you sell products. Without a good system, you might run out of stock and lose sales. But keeping too much stock can use up your money and lead to losses if products expire or become outdated. Extra unsold items can also increase your taxes. That’s why it’s smart to keep your inventory system simple and well-organized to avoid problems and keep things running smoothly.

Inventory management is also part of the bigger picture of supply chain management. While supply chain management focuses on moving goods from suppliers to customers, inventory management focuses on keeping track of your stock and its costs.

This helps you make better decisions when buying new products. For small businesses or new business owners, it’s easy to confuse inventory management with the whole supply chain. But as your business grows and more people or teams get involved, it becomes more important to understand the difference.

Why Is Manufacturing Inventory Management Important?

Good inventory management helps manufacturers control costs, avoid waste, and keep production running smoothly. If too much money is tied up in unused materials, it can cause cash flow problems. On the other hand, not having enough stock can lead to missed sales.

Costs like raw materials, storage, and transport all add to the price of making each product. Managing these well means higher profits. For example, buying materials wisely, avoiding overproduction, and forecasting demand can lower costs and reduce waste.

Strong inventory systems also help manufacturers handle supply chain problems and deliver products to customers on time. It’s about finding the right balance—keeping enough stock without having too much.

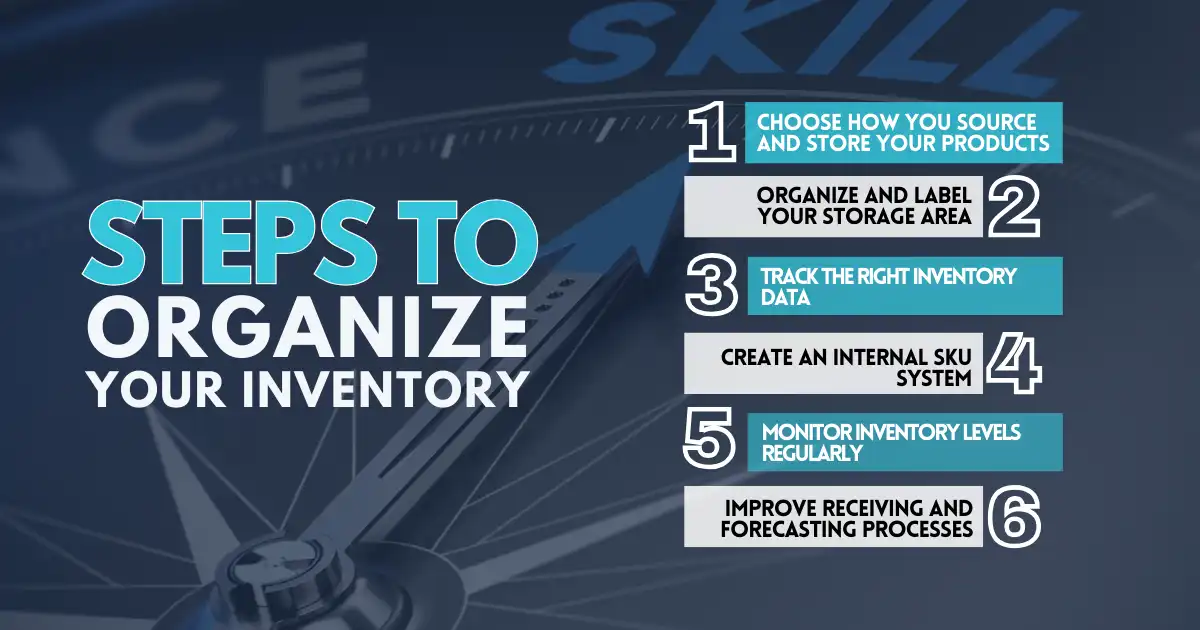

Steps to Organize Your Inventory

If you find that managing your inventory takes up most of your day, it’s probably time to rework your system. Inventory management isn’t just about knowing what’s in stock—it’s about saving time, reducing costs, and making better business decisions.

A well-organized system lets you focus on growth while keeping your operations smooth. Below are the easy steps to build a solid inventory management strategy for your business.

1. Choose How You Source and Store Your Products

How and where you get your inventory plays a big role in how you manage it.

- In-House Inventory – If you store everything at your location, you have full control. You’ll be responsible for organizing, tracking, and securing your stock.

- Fulfillment Centers – If you use third-party logistics (3PL) services or fulfillment warehouses, make sure your inventory system connects with theirs. This allows real-time updates and prevents overselling or stockouts.

- Dropshipping – If you don’t keep inventory on hand and ship directly from suppliers, your inventory depends on their stock levels. Integration and clear communication are key to avoiding customer disappointment.

Tip: Whichever method you choose, make sure your sourcing and storage approach supports your business size and order volume.

2. Organize and Label Your Storage Area

Efficient storage saves time and reduces errors.

- Use shelves, bins, and racks that are clearly labeled.

- Give every product a specific place in your storage area. This makes it easier to find items and reduces picking errors.

- SKUs (stock-keeping units) help you identify products quickly. Even if two items look similar, different SKUs can distinguish size, color, or brand.

Organized storage improves speed and accuracy in packing and shipping, especially as your business grows.

3. Track the Right Inventory Data

Keeping track of accurate data is essential—no matter how you store your items.

Use spreadsheets, cloud-based software, or dedicated inventory management systems to record and monitor the following:

- Unique product identifiers for internal use and external tracking.

- How many units do you currently have in stock?

- Where each product is stored.

- Contact details, minimum order requirements, shipping times, and reliability.

- What you pay for each product and any discounts for bulk orders.

- Standard and promotional prices to monitor profitability.

Tip: Regularly update this data to avoid miscounts or incorrect reorder levels.

4. Create an Internal SKU System

SKUs help streamline your daily operations. A well-designed SKU system allows you to:

- Identify products faster

- Reduce errors in shipping and receiving

- Simplify reorders and audits

Example SKU Breakdown:

TMP013-4101_EP

- TMP: Supplier code (e.g., Timepro)

- 013: Product category (e.g., multifunction printer)

- 4: Material or handling type

- 101: Last four digits of UPC for easy reference

- EP: Brand code (e.g., Epson)

Having your SKU format helps with internal control and can be customized to fit your workflow.

5. Monitor Inventory Levels Regularly

Relying only on an annual audit isn’t enough. Mistakes can pile up and become hard to track months later. Instead, use quicker methods to stay updated:

- Break your inventory into sections and count each section on a regular schedule (e.g., weekly or monthly). You can do this by product type, supplier, or storage area.

- Randomly check a few items from time to time to catch errors in stock levels or product location.

Benefits:

- Keeps records accurate

- Catches theft or misplacements early

- Prevents over-ordering or understocking

6. Improve Receiving and Forecasting Processes

Inventory Forecasting:

This means predicting how much stock you’ll need based on past sales, upcoming promotions, seasonal trends, and supplier lead times.

- Know which products sell fast and which are slow movers.

- Stock up before peak seasons to avoid shortages.

- As your business grows, forecasting helps you keep up with new customer demand.

Receiving Inventory:

Once new stock arrives, the way you handle it affects everything down the line.

- Always check deliveries against your purchase orders.

- Open and inspect every case. Mistakes in labeling and packing happen more often than you think.

- Update your inventory system as soon as the stock is received.

- Store items in the correct locations immediately. Use temporary storage notes if needed for overflow items.

FIFO vs. LIFO:

- FIFO (First In, First Out) – Sell the oldest stock first. Ideal for products with expiration dates like food, cosmetics, and seasonal items.

- LIFO (Last In, First Out)– Sell the newest stock first. Less common but sometimes used in industries where prices fluctuate.

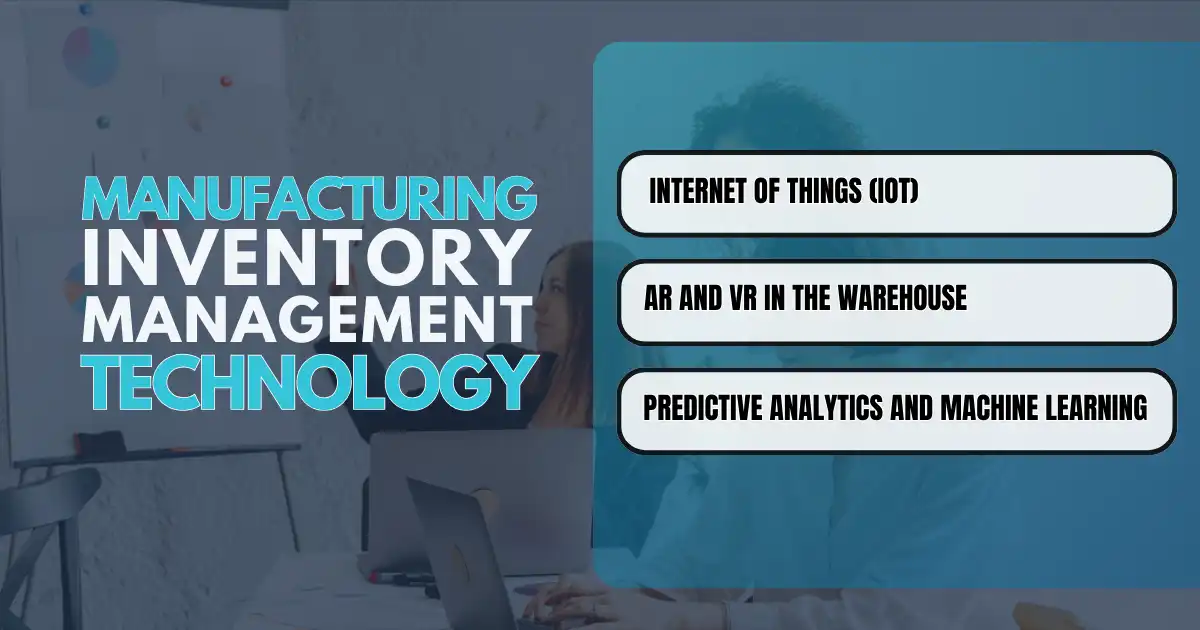

Manufacturing Inventory Management Technology

A recent report from EY revealed that 68% of CEOs at top global industrial companies ramped up their digital investments in 2023. One major area seeing the impact of these investments? Inventory management. In manufacturing, it’s a core function where smart tech upgrades can lead to serious returns. Below are some key technologies that are reshaping how manufacturers handle inventory.

Internet of Things (IoT)

IoT is changing the game for real-time inventory tracking. With tech like RFID, Bluetooth Low Energy, and smart sensors, manufacturers can monitor inventory across every stage—from raw materials to finished goods. This level of visibility makes it easier to manage quantities, locations, and movement across production lines, warehouses, and distribution hubs.

AR and VR in the Warehouse

Augmented Reality (AR) and Virtual Reality (VR) are bringing big changes to warehouse operations. When paired with robotics, VR can simplify manual inventory audits. On the other hand, AR tools can help workers keep a closer eye on stock, optimize warehouse layouts, and speed up order picking—making the entire logistics process more efficient.

Predictive Analytics and Machine Learning

Forecasting demand is no longer guesswork. With predictive analytics and machine learning (ML), manufacturers can uncover patterns in supplier pricing, customer behavior, and internal operations. As more inventory data becomes digitized, it opens the door for smarter, more informed decisions that help businesses grow, cut costs, and boost supply chain performance.

Best Practices for Manufacturing Inventory Management

Inventory management is an evolving process in manufacturing, continuously refined to meet shifting market demands. Below are several important practices that have gained importance as the field develops.

Routine Audits and Cycle Counting

Conducting regular inventory audits and cycle counts is essential for maintaining accuracy and accountability. Even when using a perpetual inventory system, periodic checks help verify data, assess the reliability of internal processes, and catch transaction errors.

The most comprehensive method is an annual or semiannual full physical count, though it can disrupt operations. Cycle counting offers an alternative, involving frequent counts of smaller inventory segments—daily, weekly, or monthly. While some companies use cycle counting to replace full audits, most use it to complement more extensive physical checks.

Collaborative Approach Across Departments

Successful inventory management depends on active collaboration between inventory or supply chain teams and other departments. While inventory teams are responsible for execution, they rely on close coordination with production, sales, procurement, and finance.

For instance, production dictates what can be manufactured, sales and marketing provide insights into customer demand, procurement handles supplier relationships and material sourcing, and finance monitors inventory-related costs and trends. Strong leadership and processes are needed to align these departments and ensure smooth operations.

Ongoing Training and Skill Development

Well-trained inventory staff can offer manufacturers a strategic advantage. Ongoing development in areas like data analysis, lean manufacturing, digital tools, and advanced accounting helps teams implement better inventory strategies, utilize technology effectively, and maintain control over stock levels. This leads to improved production efficiency and profitability.

Leveraging Digital Technologies

New technologies—such as the Industrial Internet of Things (IIoT), 5G, AI-driven analytics, and automation—are reshaping inventory management in manufacturing. These tools enhance visibility, improve demand forecasting, and streamline supply chain logistics.

For example, AI can refine predictions, while integration with supplier systems improves sourcing and reduces costs. Tools like augmented reality and autonomous warehouse vehicles can also speed up inventory handling and tracking.

Strengthening Supplier Relationships

Developing strong supplier partnerships is an important element of effective inventory control. Sharing selected data through collaborative inventory systems can help align forecasting, reduce lead times, and prevent raw material shortages. These partnerships improve planning accuracy and support more efficient logistics and production processes.

Don’t Let Your Stockroom Sink Your Ship

Running a business without a clear inventory plan is like sailing blindfolded—you’re bound to crash. Every missed order, wasted product, and stockout chips away at trust, profit, and growth. That’s not a risk—it’s a recipe for disaster.

If you’re still juggling spreadsheets and guesswork, it’s time to wise up. Today’s leaders are using inventory management software manufacturing systems that do more than track—they predict, sync, and simplify. The best manufacturing and inventory software doesn’t just organize—it helps you outsmart shortages and sharpen your raw material stock management.

Don’t wait for a wake-up call. If you want smoother operations, faster decisions, and fewer fire drills, get serious about inventory now. Businesses that adapt will thrive—those that don’t? They’ll be left picking up the pieces. So, are you running your stock—or is your stock running you?

FAQs

What’s the best way to manage inventory for a growing business?

The best way to manage inventory is to use a reliable system that tracks stock levels in real time, sets reorder points, and provides sales forecasting. This helps you avoid overstocking and stockouts. Many companies turn to inventory management software to streamline processes and make smarter decisions.

Why is inventory stocking important for small businesses?

Inventory stocking helps ensure you always have the right products available when customers order. Poor stocking can lead to missed sales or wasted money on slow-moving items. A good stocking plan keeps your shelves balanced—enough to meet demand, but not so much that it ties up cash.

What can happen if you keep running out of inventory?

Running out of inventory can result in lost sales, upset customers, and damaged reputation. It can also delay production if you’re a manufacturer. Repeated stockouts often push customers toward competitors who always have products ready.

How can a company improve its inventory management practices?

Strong company inventory management starts with organizing storage, labeling items clearly, tracking data accurately, and reviewing stock regularly. Investing in modern tools can improve forecasting, reduce waste, and help teams make faster, smarter decisions.